Full Circle Tool and Machine

Throughout the years Full Circle has always been known for its “can do” attitude.

We continue to build and maintain our business relationships by collaborating with our customers, both new and existing, to reach high quality, economical solutions for the challenges they face.

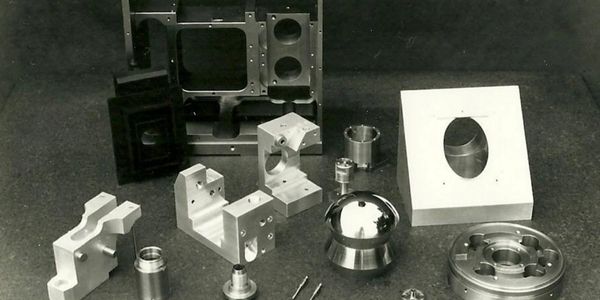

Our capabilities include CNC milling, CNC turning, conventional turning, milling, surface grinding, cylindrical grinding (both ID and OD), as well as Jig Grinding, Jig & fixture building, specialty gages, model making, prototypes through production quantities.

Full Circle Tool and Machine #jig

Full Circle routinely machines most types of metals, including aluminum, titanium, stainless steel, carbon based steels, tool steel, and many of the high temperature nickel-based alloys. Additionally, Full Circle has many years of experience machining precision components from various plastics. We are very familiar with the characteristics of materials used in the semiconductor and medical manufacturing communities, such as Vespel®, Torlon®, Meldin®, and Peek®. As well as the more common plastics such as Delrin®, Nylon, PVC, Lexan® and a host of others. We understand and appreciate both the cost – and value – of these materials.

Commitment to Quality

In addition to our own capabilities, Full Circle Tool & Machine has developed a network of outside services. Our vendors share our commitment to quality, and on time delivery. We have some of the leaders in their respective industries providing heat treating, anodizing & plating, various welding services such as arc, MIG, TIG, and E-Beam; brazing, both vacuum and dip type. Just to highlight a few.

Any questions? Please contact us so we can offer our assistance.

Contact Us

Drop us a line!

Hours

Today | Closed |

Copyright © 2020 Full Circle Tool and Machine - All Rights Reserved.

Powered by GoDaddy Website Builder